Toluene HDA Process Simulation Guide

Welcome to Toluene Hydrodealkylation guide!

This guide will help you simulate the Toluene Hydrodealkylation process in HYSYS, including the conversion of toluene to benzene. You will learn about the flowsheet and equipment data, and how to use shortcut distillation columns to build T-101 and T-102.

Problem Statement

This process simulation is about Toluene Dehyroalkylation (HDA). The toluene dehydroalkylation process involves the conversion of toluene to benzene and methane, benzene being the desired product. However, another side reaction occurs which is conversion of benzene to biphenyl. The primary reaction operates at 98% conversion and the side reaction is at 2% conversion.

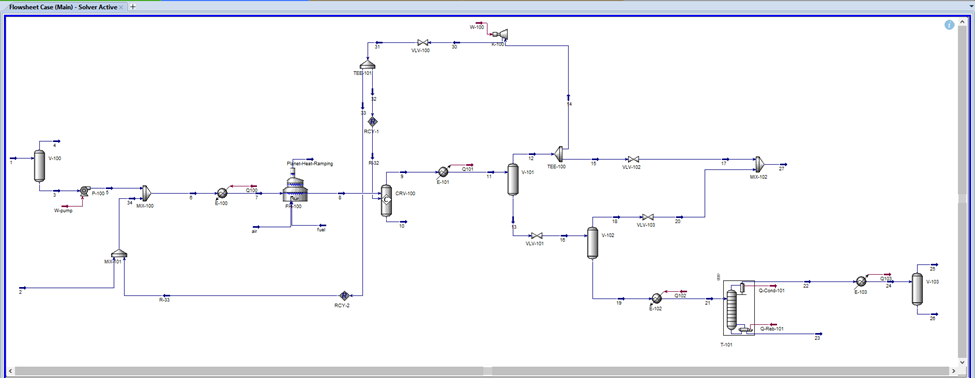

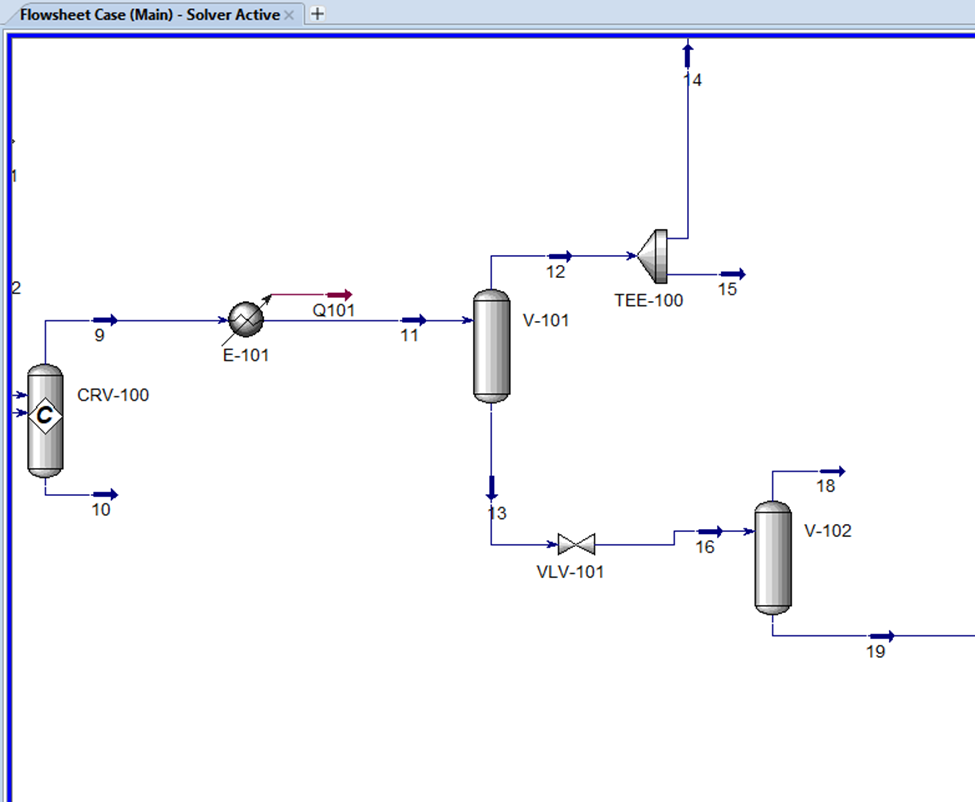

Flowsheet

Properties Environment Setup

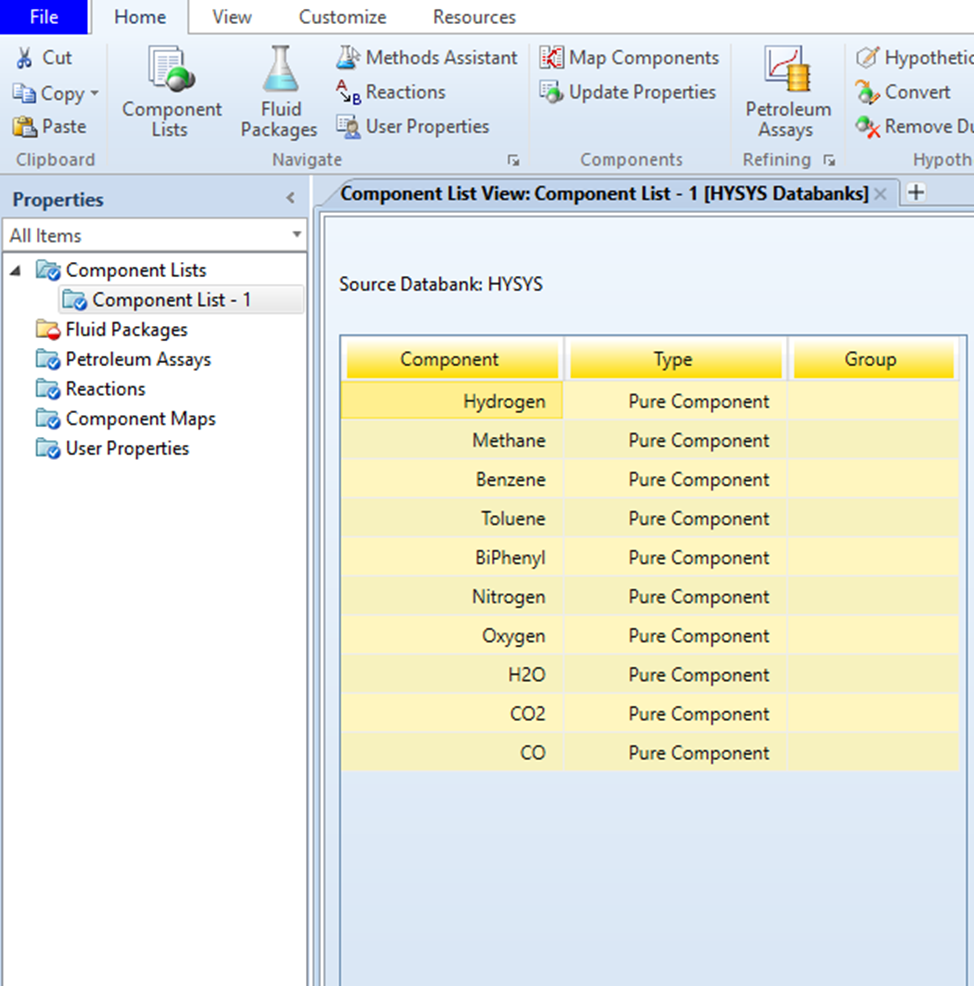

Component Selection

Open new project and add the components from problem statement.

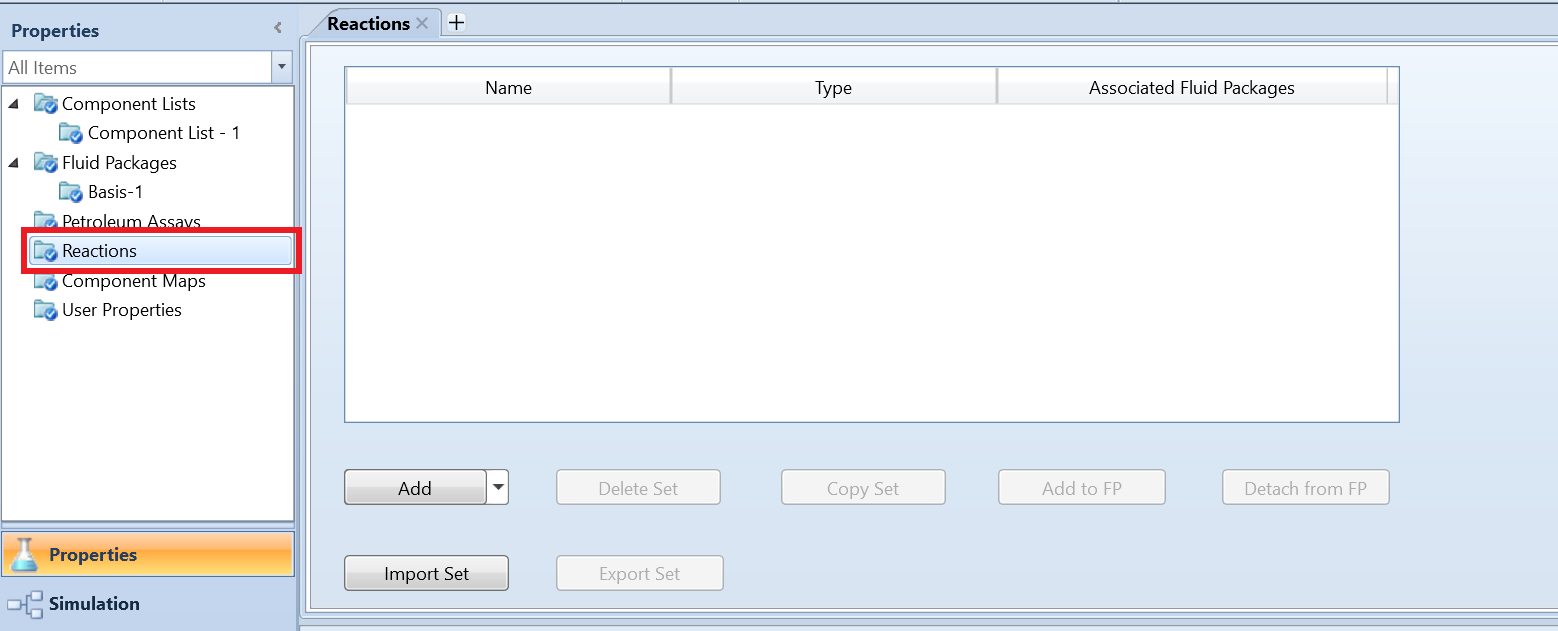

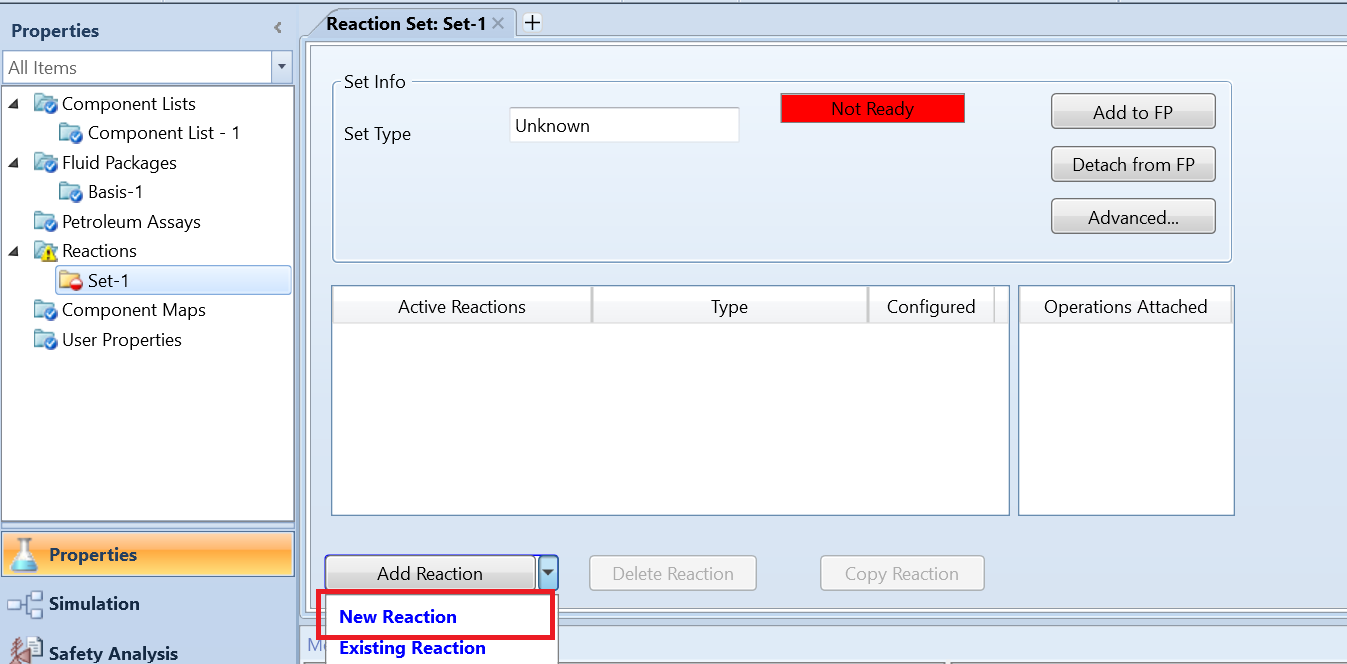

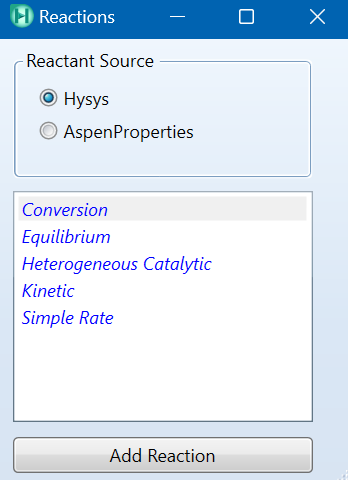

Reaction Setup

Add reactions to your process system.

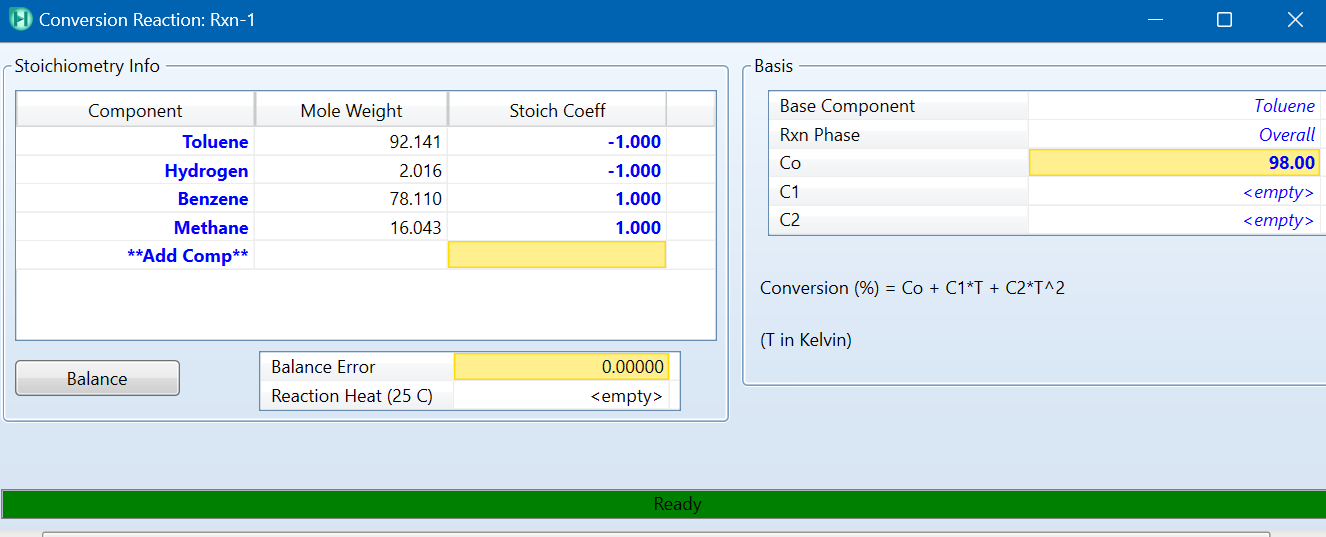

Configure First Reaction

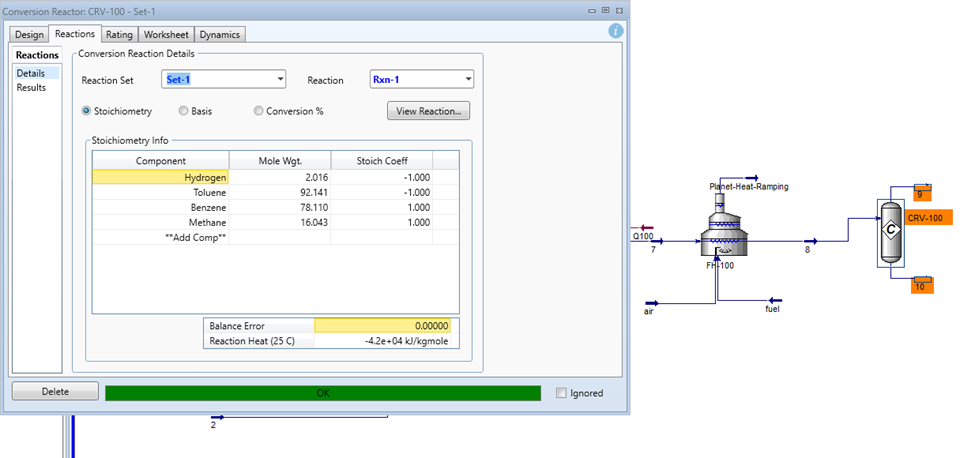

After adding first reaction (toluene to benzene), specify the conversion (98%) and stoichiometry.

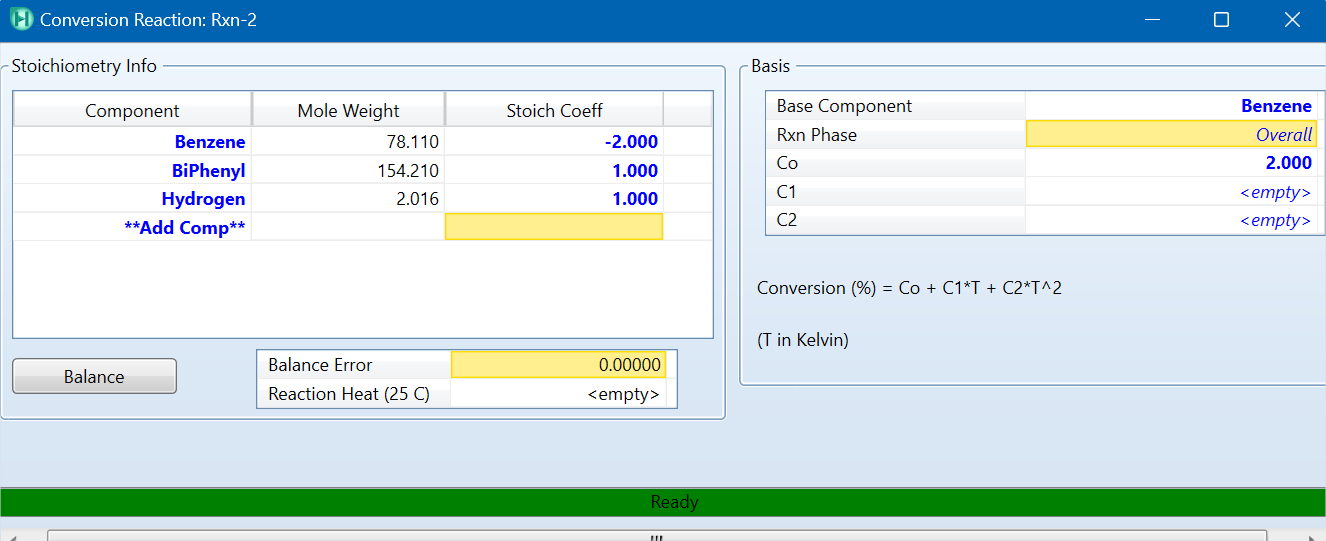

Configure Second Reaction

Verify the second reaction configuration.

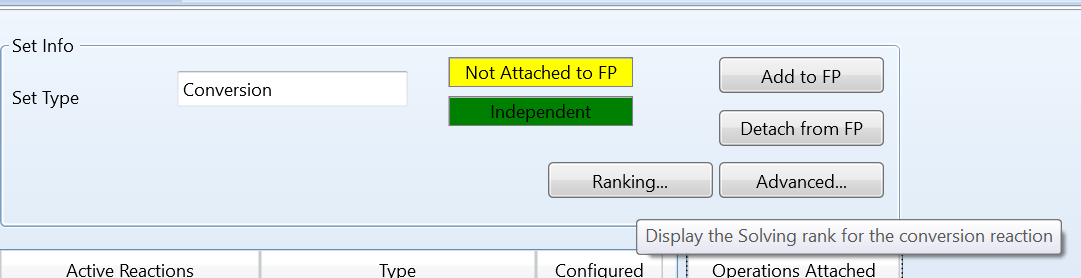

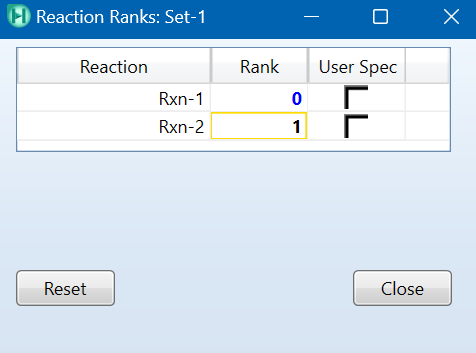

Reaction Ranking

Define the Ranking of reactions and attach reaction set to fluid package.

Simulation Environment

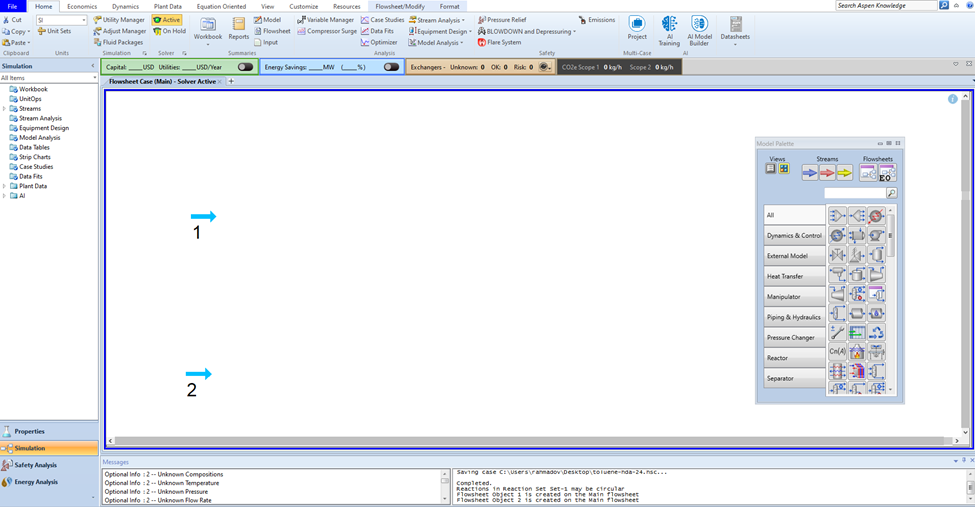

Initial Stream Setup

Add first two streams to flowsheet and define their composition and conditions:

Stream Conditions

| Streams | T [°C] | P [kPa] |

|---|---|---|

| 1 | 25 | 190 |

| 2 | 25 | 2550 |

Stream Compositions

| Compounds | S1 [kmol/hr] | S2 [kmol/hr] |

|---|---|---|

| Hydrogen | 0 | 286 |

| Methane | 0 | 15 |

| Benzene | 0 | 0 |

| Toluene | 108.7 | 0 |

| Biphenyl | 0 | 0 |

| N2 | 0 | 0 |

| O2 | 0 | 0 |

| H2O | 0 | 0 |

| CO2 | 0 | 0 |

| CO | 0 | 0 |

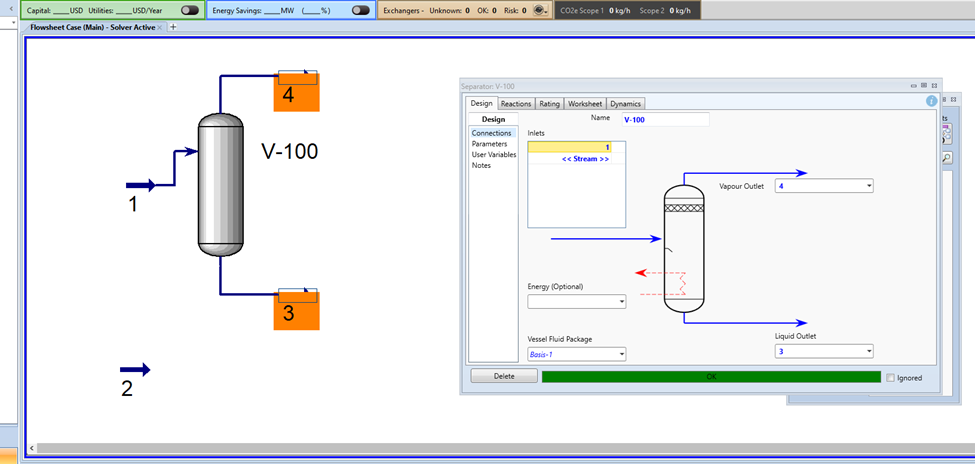

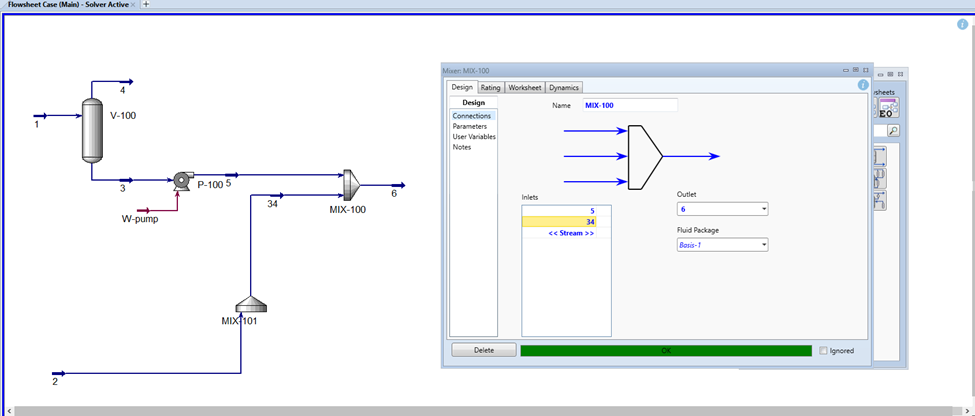

Separator Installation

Install separator for toluene inlet to ensure no gas enters the pump.

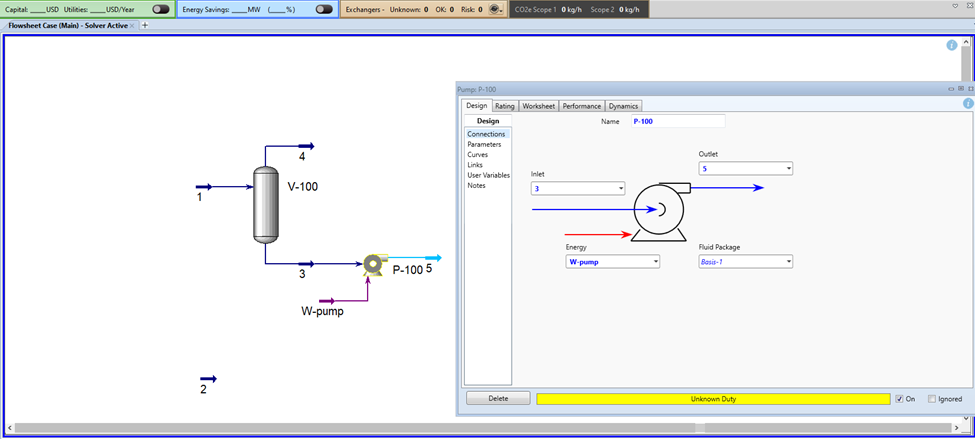

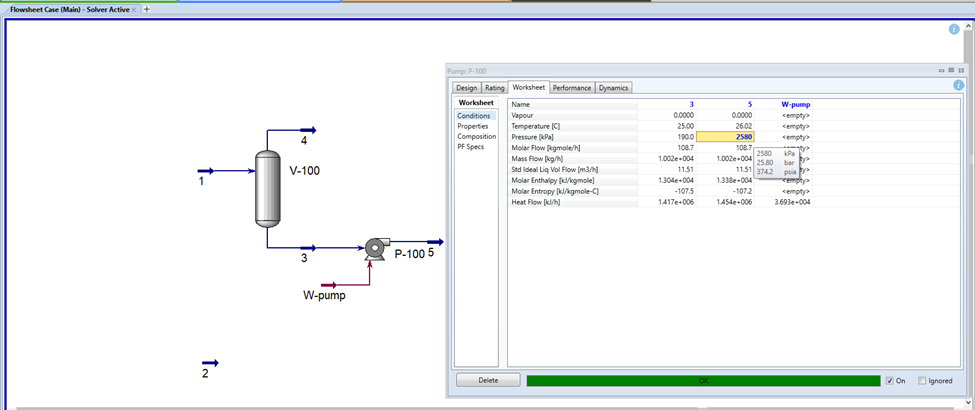

Pump Configuration

Add pump and set outlet pressure to 25.80 bars.

Mixer Setup

Add two mixers (tees/joints). Note: Do not add recycle streams yet.

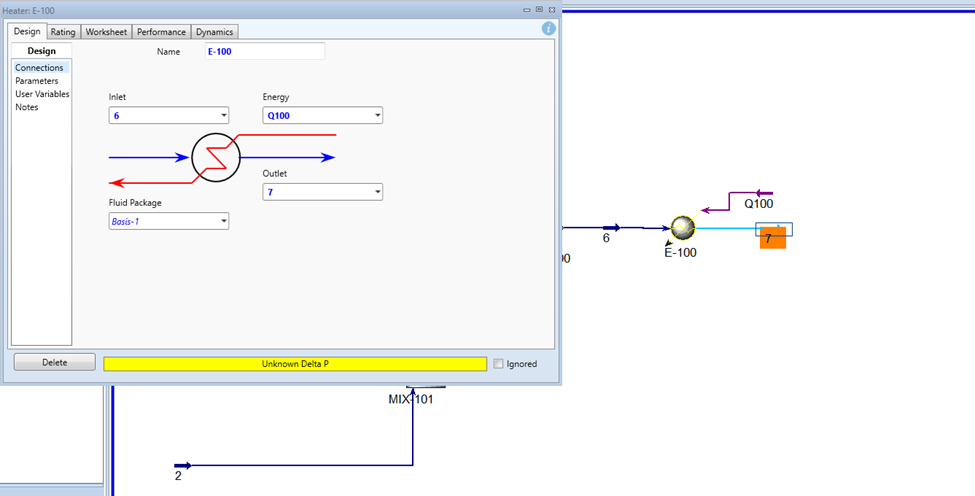

Pre-heater Configuration

Add pre-heater to heat the mix to 225°C. Set ΔP = 30 kPa.

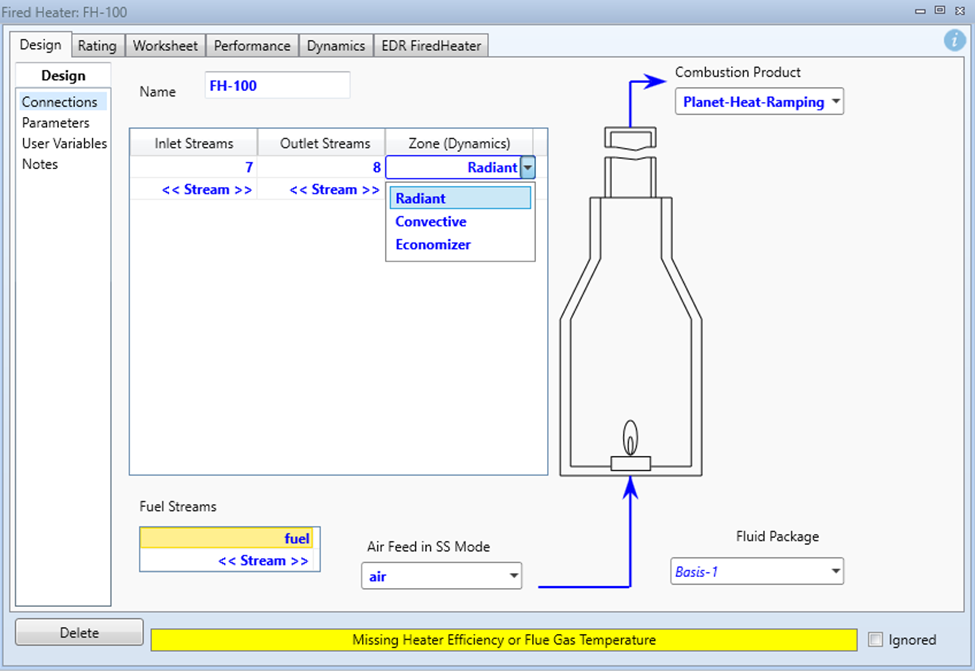

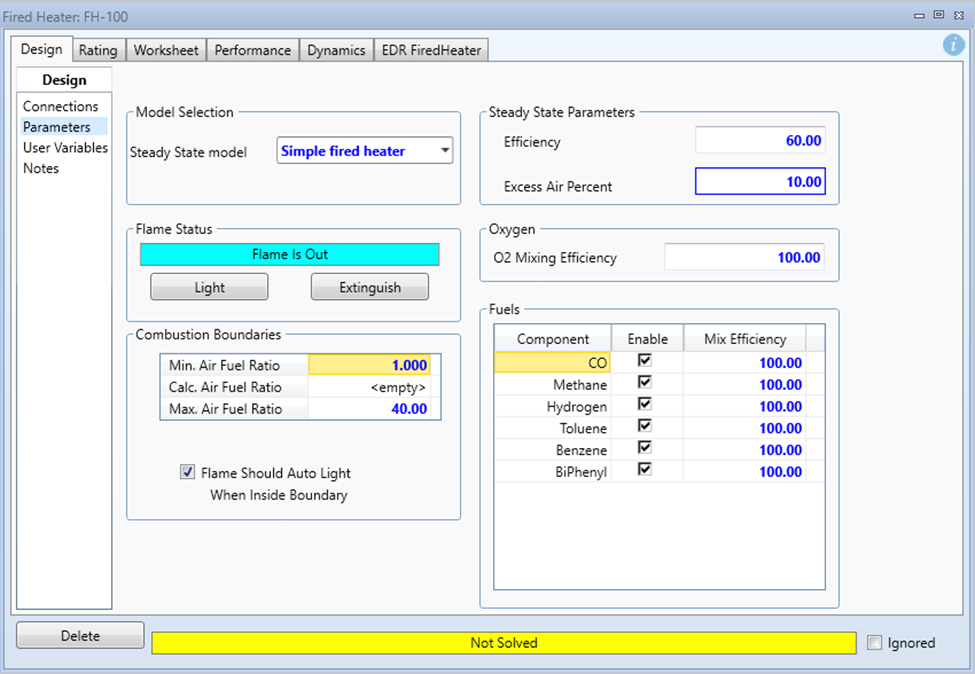

Furnace Setup

Add fired heater and configure the radiative zone. Define air, fuel, and flue gas streams.

Air and Fuel Compositions

| Compounds | Air | Fuel |

|---|---|---|

| Hydrogen | 0 | 0.2 |

| Methane | 0 | 0.8 |

| N2 | 0.79 | 0 |

| O2 | 0.21 | 0 |

Stream Conditions

| Streams | T [°C] | P [kPa] |

|---|---|---|

| Air | 25 | 101.3 |

| Fuel | 25 | 101.3 |

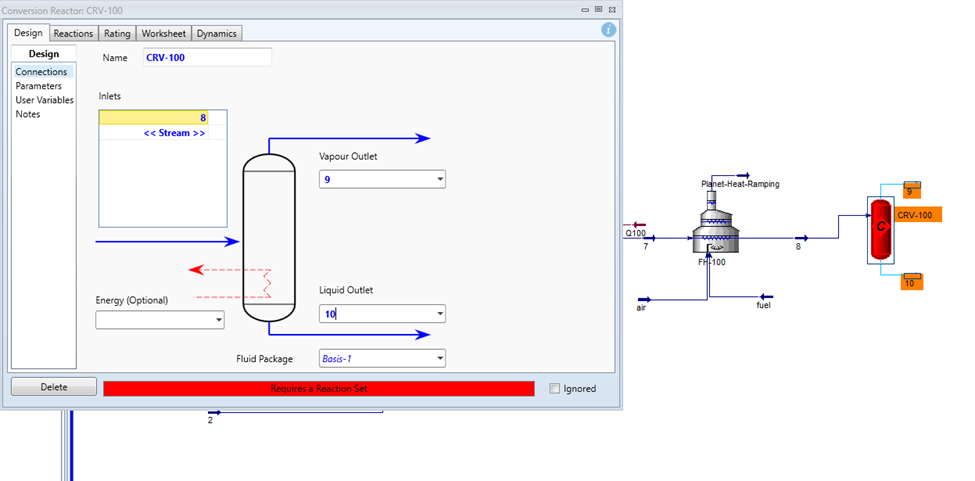

Reactor Configuration

Add conversion reactor and select the reaction set.

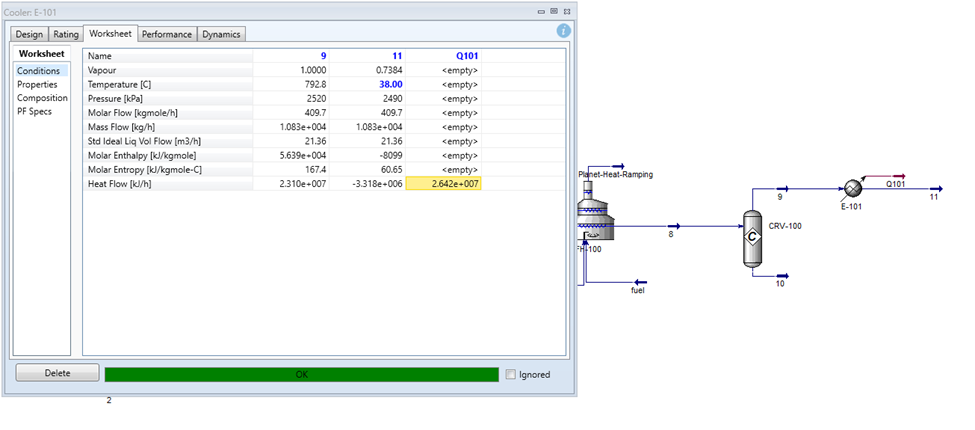

Cooler Setup

Add cooler E-101. Set pressure drop to 30 kPa and temperature to 38°C.

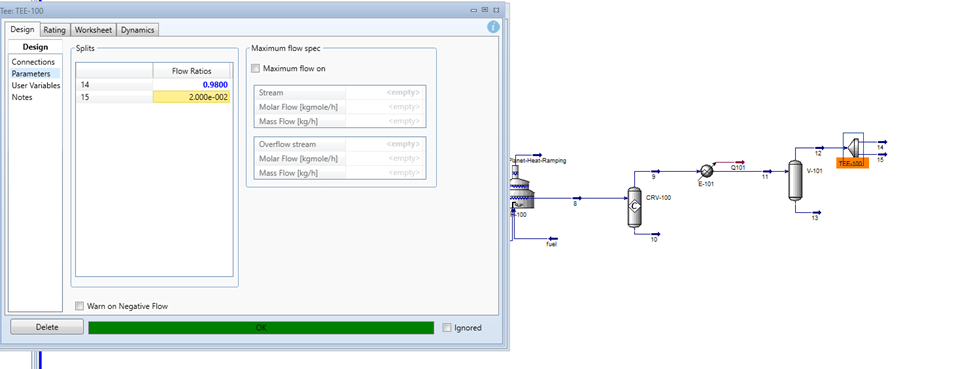

Recycle Configuration

Add separator V-101 and tee for recycle stream (98% of separator outlet gas).

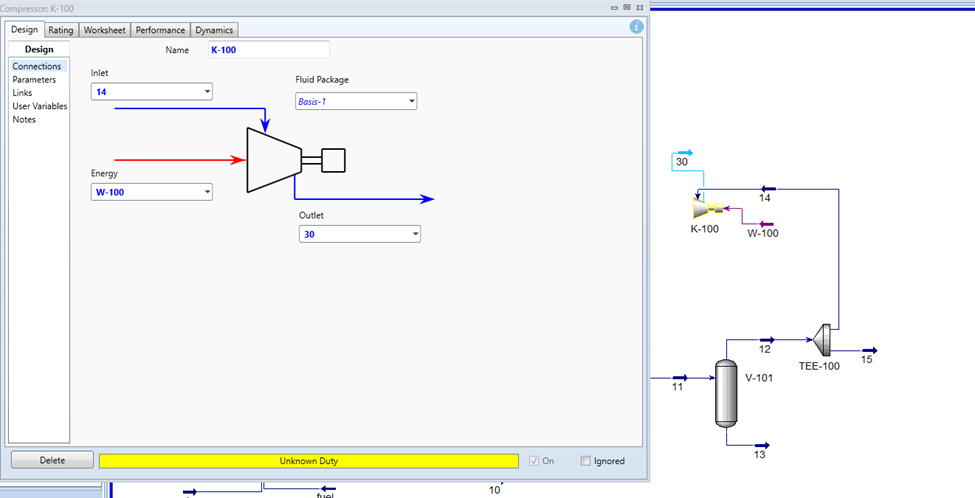

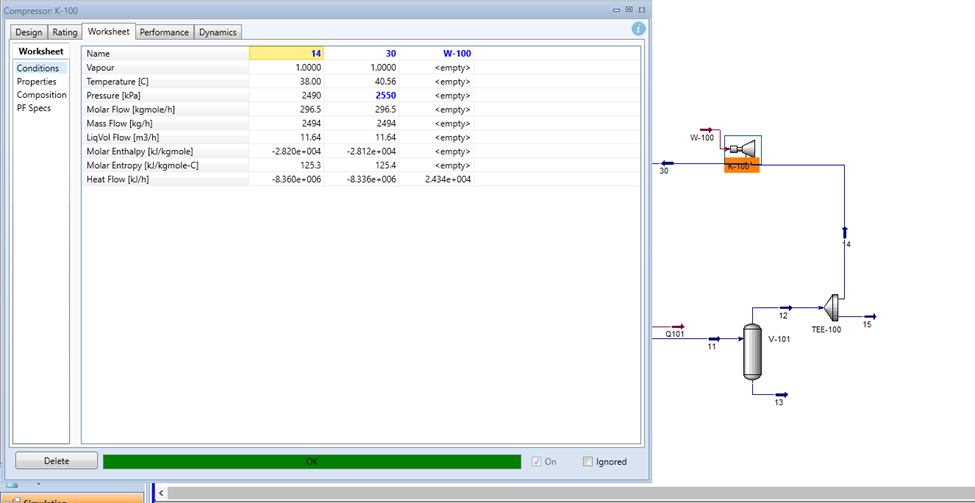

Compressor Setup

Add compressor to increase gas pressure to 25.50 bars.

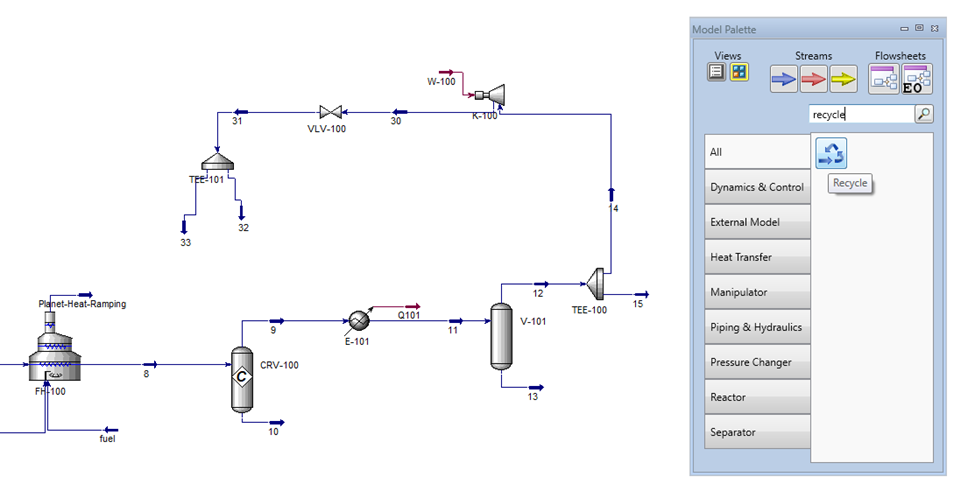

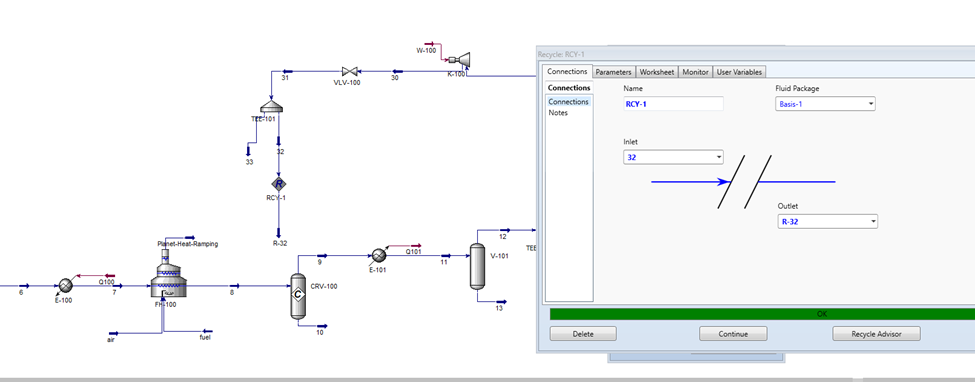

Final Recycle Setup

Add valve VLV-100 (ΔP = 10 kPa) and configure the final recycle streams.

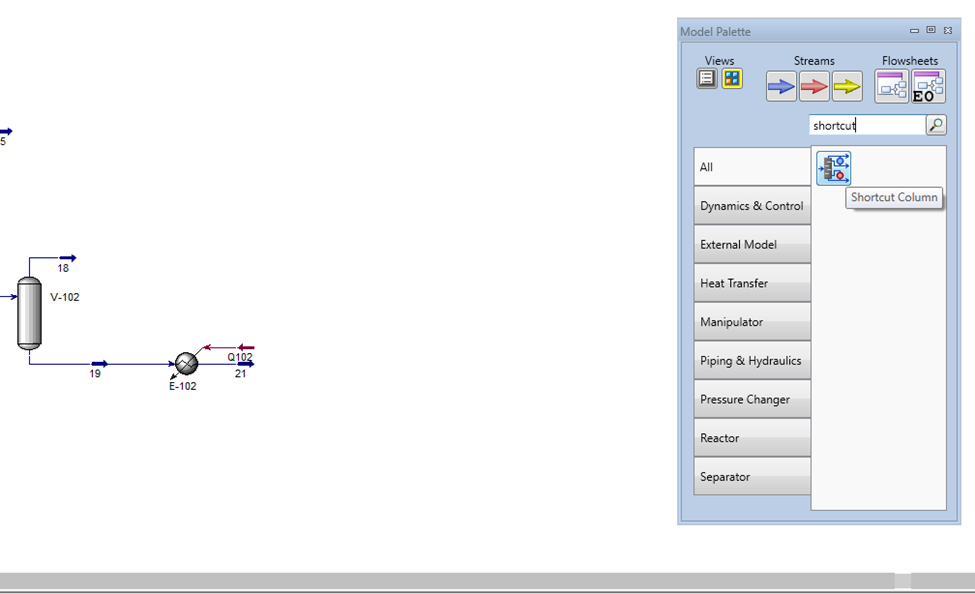

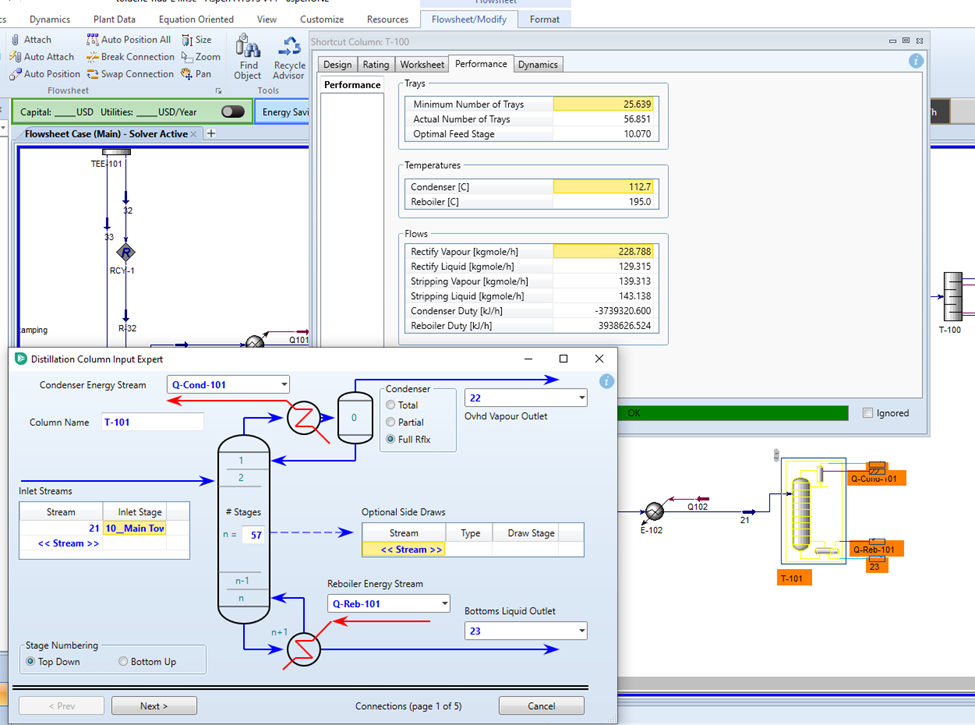

Distillation Setup

Add valve VLV-101 (throttle to 320 kPa) and separator V-102.

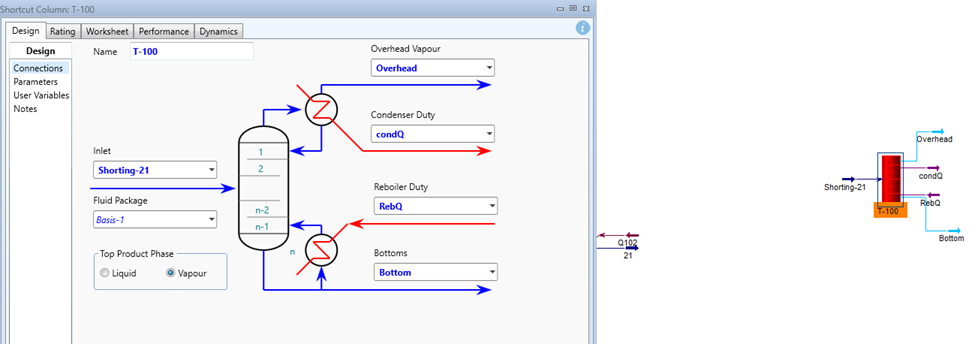

Configure the shortcut column for initial estimates:

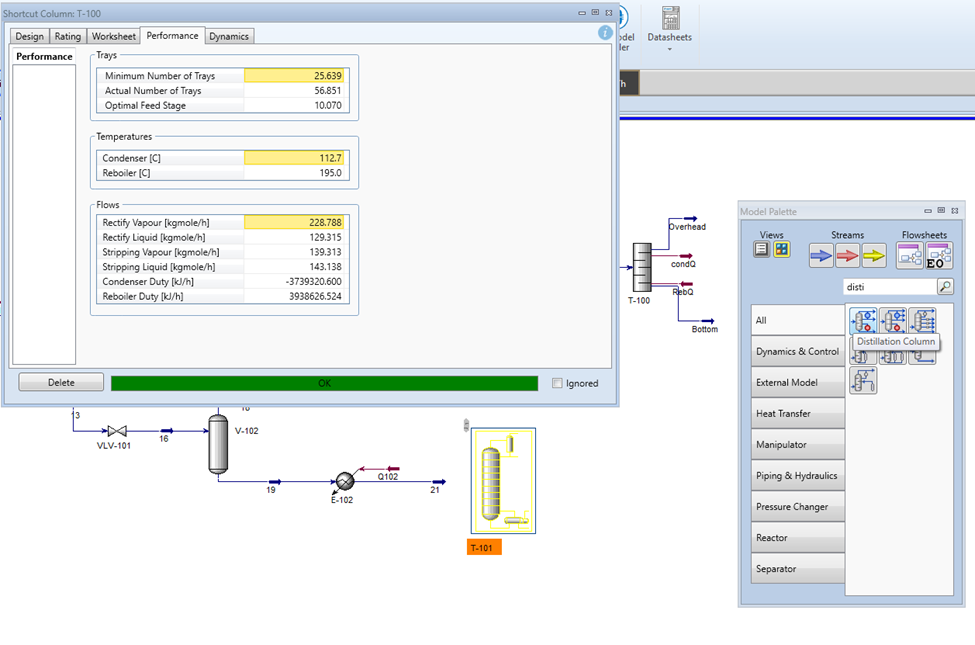

Final Column Configuration

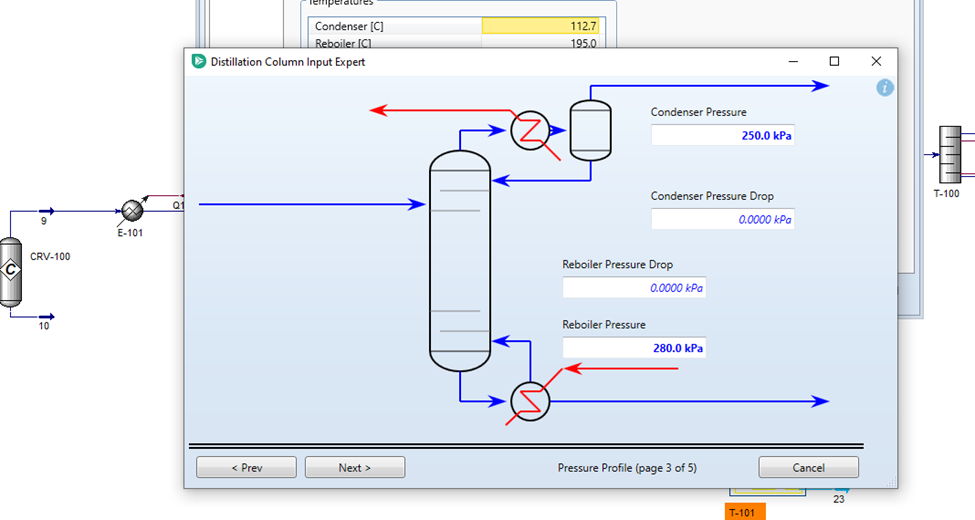

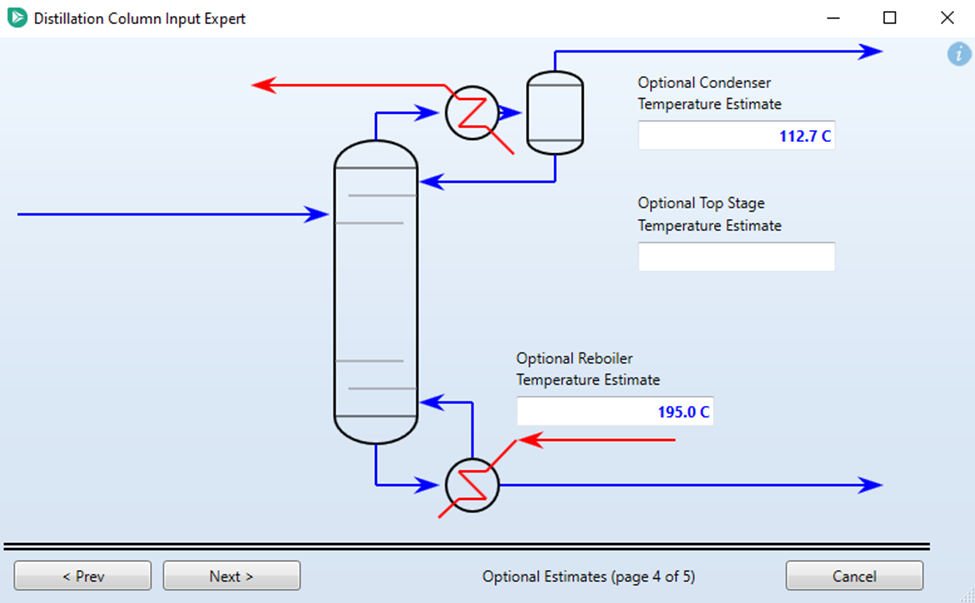

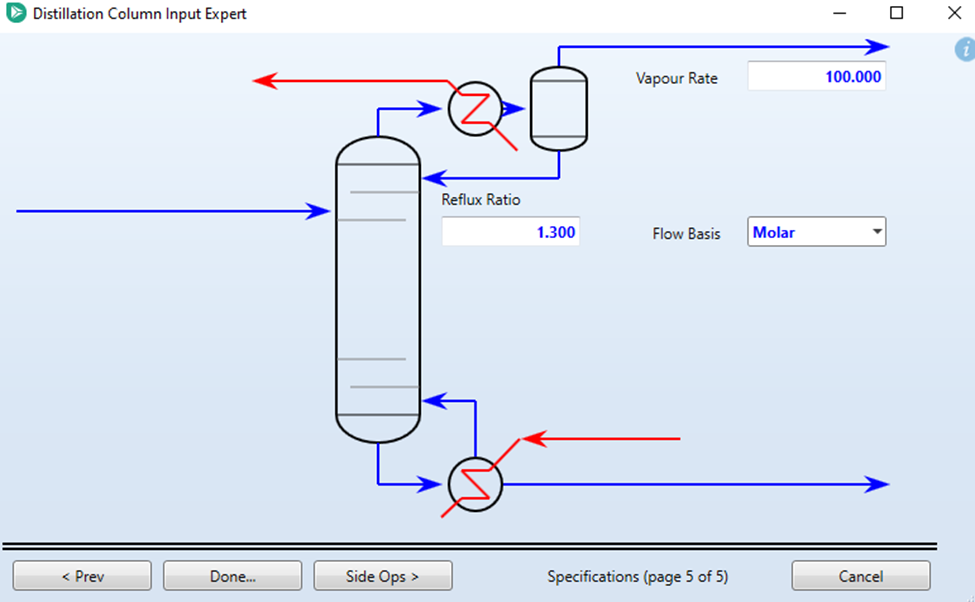

Use the shortcut column results to configure the rigorous distillation column:

Set condenser and reboiler pressures to 250 kPa and 280 kPa respectively.